TOP CATEGORY: Chemicals & Materials | Life Sciences | Banking & Finance | ICT Media

Industry Overview

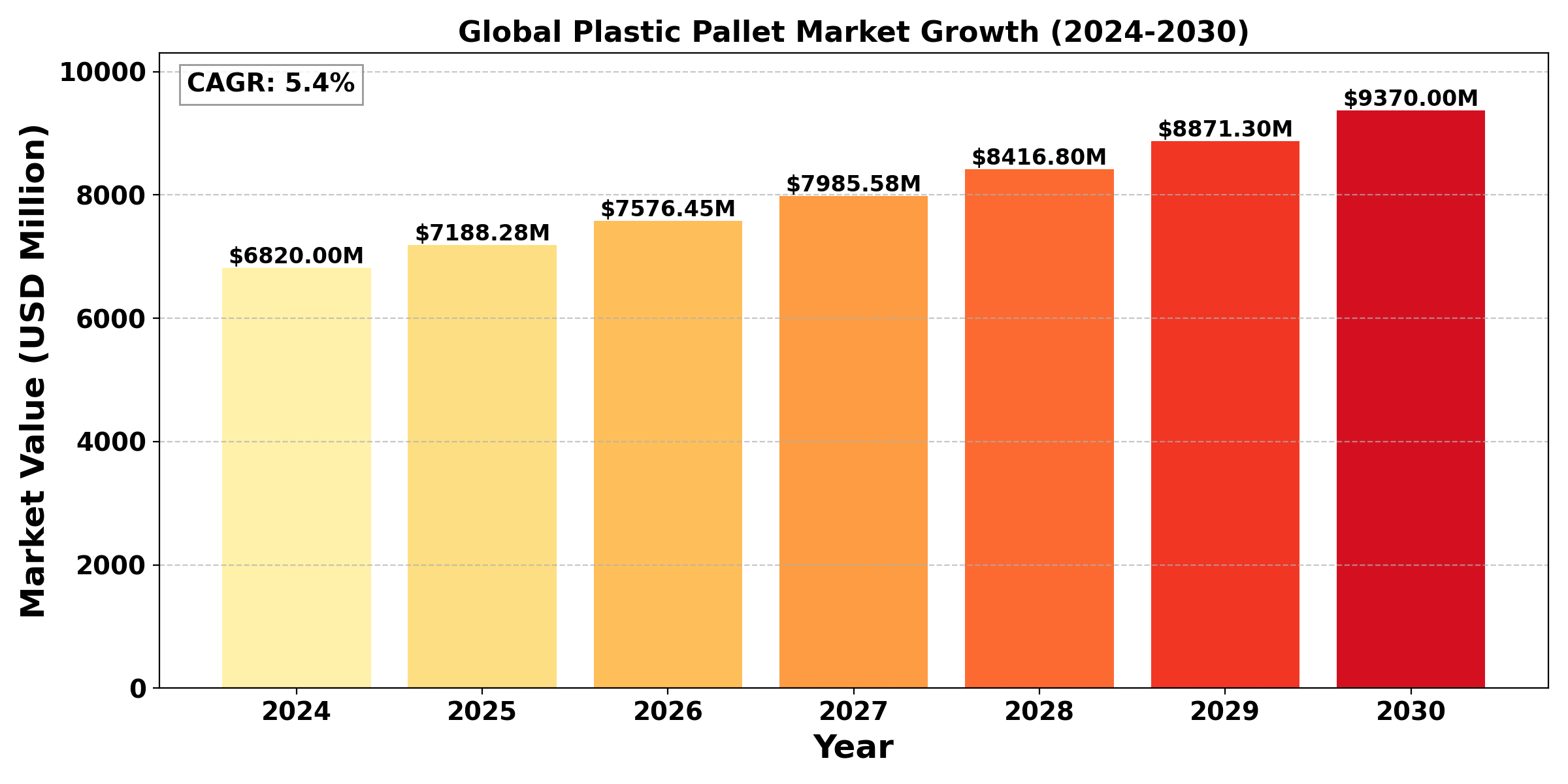

The "Global Plastic Pallet Market" size was valued at US$ 6.82 Billion in 2024 and is projected to reach US$ 9.37 Billion by 2030, at a CAGR of 5.4% during the forecast period 2024-2030.

The growing need for long-lasting and environmentally friendly packaging solutions across a range of industries is propelling the worldwide plastic pallet market's notable expansion. Plastic pallets are perfect for use in food and pharmaceuticals because they have a number of advantages over traditional wooden pallets, such as increased durability, moisture resistance, and a lower chance of contamination. The market has been further driven by the growth of the retail and e-commerce industries, as effective supply chain management and logistics have become critical. Additionally, companies are being encouraged to use plastic pallets, which are frequently manufactured from recycled materials and may be recycled at the end of their life cycle, as a result of the increased focus on sustainability and recycling.

Plastic pallets are being used more and more by important industries like consumer products, electronics, and automobiles to streamline operations and lower maintenance and replacement costs. The market is confronted with obstacles, nonetheless, like the high beginning prices in comparison to hardwood pallets and competition from substitute materials. As more businesses realize the long-term advantages of purchasing plastic pallets for their supply chain and logistics requirements, the market for plastic pallets is expected to grow further.

HDPE to hold the highest market share: By Type

High-density polyethylene (HDPE) and polypropylene (PP) pallets are the most common types of plastic pallets in the global market. Due in large part to its exceptional durability, chemical resistance, and temperature tolerance, HDPE pallets have the largest market share among them and can be used in a variety of sectors. In industries where robustness and hygiene are crucial, such food and beverage, medicines, and logistics, HDPE pallets are especially preferred. Additionally, because they are lightweight, handling efficiency is increased and shipping expenses are reduced.

Although polypropylene pallets are also becoming more popular because of their adaptability and reduced manufacturing costs, they are typically used in particular applications where cost-effectiveness and lighter weight are more important than HDPE's greater durability. HDPE's recyclability and extended lifespan further increase its appeal as supply chains become more sustainable, enabling it to maintain a sizable market share advantage over PP pallets.

Overall, HDPE's performance qualities, adaptability to a variety of sectors, and rising awareness of the value of dependable and environmentally friendly packaging options account for its market domination in the plastic pallet industry. HDPE pallets are probably going to continue to be the go-to option for many companies worldwide as the need for eco-friendly products and effective logistics grows.

Food Industry to hold the highest market share: By Application

The food business has the largest market share in the global plastic pallet market, according to segment percentages by application. The strict safety and hygienic requirements for handling and storing food are the main cause of its predominance. In this industry, plastic pallets are chosen due to their non-porous nature, ease of cleaning, and moisture resistance, which lowers the possibility of contamination and spoiling. They are also perfect for a variety of uses, from distributing completed goods to transporting raw materials, due to their resilience to chemicals and durability.

Due to the necessity for clean and secure transportation of medical equipment, medications, and supplies, the medical sector accounts for a sizeable share of the market, second only to the food sector. Because of their ability to maintain sanitation and their compliance with regulatory norms, plastic pallets are crucial in this industry.

To a lesser degree, the electronics and chemical industries also contribute to the market. The chemical industry uses plastic pallets because of their chemical resistance, which guards against contamination and spills. They offer a secure and effective way to move delicate parts in the electronics sector without running the danger of splinters or other damage that comes with using wooden pallets.

Regional Analysis

The global aerosol can market exhibits diverse dynamics across different regions, influenced by varying consumer preferences, regulatory frameworks, and economic conditions.

North America continues to be a sizable market due to the strong demand for household and personal care goods. Modern industrial techniques and a focus on sustainability benefit the area, spurring advancements in environmentally friendly packaging. Stricter environmental effect rules in Europe are driving firms to use sustainable materials and methods, while growing consumer awareness is encouraging the development of environmentally friendly packaging options.

With rising disposable incomes, urbanization, and a growing middle class driving demand for food and personal care items, Asia-Pacific is expanding quickly. Growth prospects are also offered by emerging countries in the Middle East and Latin America, although obstacles including infrastructure constraints and economic volatility may hinder market expansion. In general, the market for aerosol cans is distinguished by geographical variances that producers must manage in order to take advantage of regional opportunities and consumer trends.

Competitive analysis

Recent Development

➣ Jan 2024, IFCO, the global leading provider of reusable packaging containers (RPCs), announced to launch Dora, a cutting-edge reusable plastic pallet. Dora's smooth integration into the present fresh grocery supply chain guarantees sustained gains in logistical effectiveness and sustainability advantages for suppliers and retailers alike.

➣ October 2022, The ORBIS Corporation announced the expansion of its Urbana, Ohio, manufacturing facility. The extension will offer 30% additional room for the production of totes, bulk containers, and pallets at the 200 Elm St. ORBIS plant, which is already operational. Additionally, in order to increase efficiency, Allied Plastics enlarged its distribution facility in Wilmot, U.S., in July 2022, from 85,000 square feet to a larger space spanning 173,000 square feet.

End Use Industry Analysis

The global plastic pallet market is influenced by various end-use industries, with the food industry leading in demand due to stringent hygiene standards. Plastic pallets are preferred for transporting and storing food products because they are easy to clean, moisture-resistant, and comply with safety regulations. The medical industry follows closely, where plastic pallets ensure safe transport of pharmaceuticals and medical devices, crucial for maintaining sterility and preventing contamination. In the chemical sector, plastic pallets' resistance to hazardous materials and spills enhances safety during transportation. The electronics industry also contributes significantly, utilizing plastic pallets to protect sensitive components from damage during handling. Additionally, retail and automotive sectors are increasingly adopting plastic pallets for their durability and cost-effectiveness. As sustainability concerns rise, many industries are opting for plastic pallets over traditional wooden alternatives, further driving market growth and highlighting the importance of reliable, hygienic, and efficient packaging solutions across various applications.

Industry Dynamics

Industry Drivers

Sustainability and Environmental Concerns

The global plastic pallet market is driven by several key factors, one of the most significant being sustainability and environmental concerns. As businesses and consumers become more aware of the impact of packaging waste on the environment, there is a growing push towards adopting sustainable practices. Companies are increasingly focused on minimizing their carbon footprint and meeting corporate social responsibility (CSR) goals, which often includes transitioning to environmentally friendly packaging solutions.

Plastic pallets play a crucial role in this transition due to their manufacturing processes, which frequently utilize recycled materials. This not only reduces the demand for virgin plastic but also supports the circular economy by giving new life to discarded plastics. Furthermore, plastic pallets are designed to be fully recyclable at the end of their lifecycle, meaning they can be processed and reused rather than ending up in landfills. This aligns with stringent regulations and consumer preferences for sustainable products, making plastic pallets an attractive option for logistics and supply chain operations.

Industry Trend

Technological Advancement

Plastic pallets are becoming more and more popular across a range of industries as a result of technological advancements that greatly improve their functionality and performance. Plastic pallets are now a dependable option for heavy-duty applications thanks to increasingly complex designs that increase strength and longevity as a result of advancements in manufacturing processes.

The incorporation of Radio Frequency Identification (RFID) technology onto plastic pallets is among the most noteworthy developments. Pallets can now be tracked in real time across the supply chain, giving companies the ability to keep an eye on inventory levels, follow product movements, and find the best storage options. RFID-enabled plastic pallets improve logistics efficiency, lower the risk of stockouts or overstocking, and simplify the supply chain process by enabling improved visibility and control over inventory.

Furthermore, smart pallet systems are growing in popularity. These systems use sensors and Internet of Things (IoT) technology to track a number of variables, including location, temperature, and humidity. For sectors like food and pharmaceuticals that need to strictly conform to environmental regulations, this data can be quite helpful. Smart pallets can help avoid spoiling, decrease waste, and increase regulatory compliance by offering actionable insights.

Industry Restraint

High Initial Cost

A major obstacle to the widespread use of plastic pallets is their high initial costs, especially for smaller companies or those with limited funding. Compared to conventional wooden pallets, plastic pallets typically demand a larger initial investment. In price-sensitive markets, where businesses frequently want to reduce costs, this price differential might be a crucial consideration.

Despite the potential long-term advantages, many small and medium-sized businesses (SMEs) may be discouraged from switching from wooden pallets due to the higher cost of plastic pallets. Durability, fewer maintenance requirements, and increased lifetime are some of these advantages, which over time may result in lower overall costs of ownership. However, for companies that run on narrow margins or have little access to financing, the initial capital outlay might be a major obstacle.

Report Scope

The report includes Global & Regional market status and outlook for 2017-2028. Further, the report provides breakdown details about each region & countries covered in the report. Identifying its sales, sales volume & revenue forecast. With detailed analysis by Type, Application. The report also covers the key players of the industry including Company Profile, Product Specifications, Production Capacity/Sales, Revenue, Price, and Gross Margin 2017-2028 & Sales with a thorough analysis of the market’s competitive landscape and detailed information on vendors and comprehensive details of factors that will challenge the growth of major market vendors.

|

Attributes |

Details |

|

Segments |

By Type

By Application

|

|

Region Covered |

|

|

Key Market Players |

|

|

Report Coverage |

|