TOP CATEGORY: Chemicals & Materials | Life Sciences | Banking & Finance | ICT Media

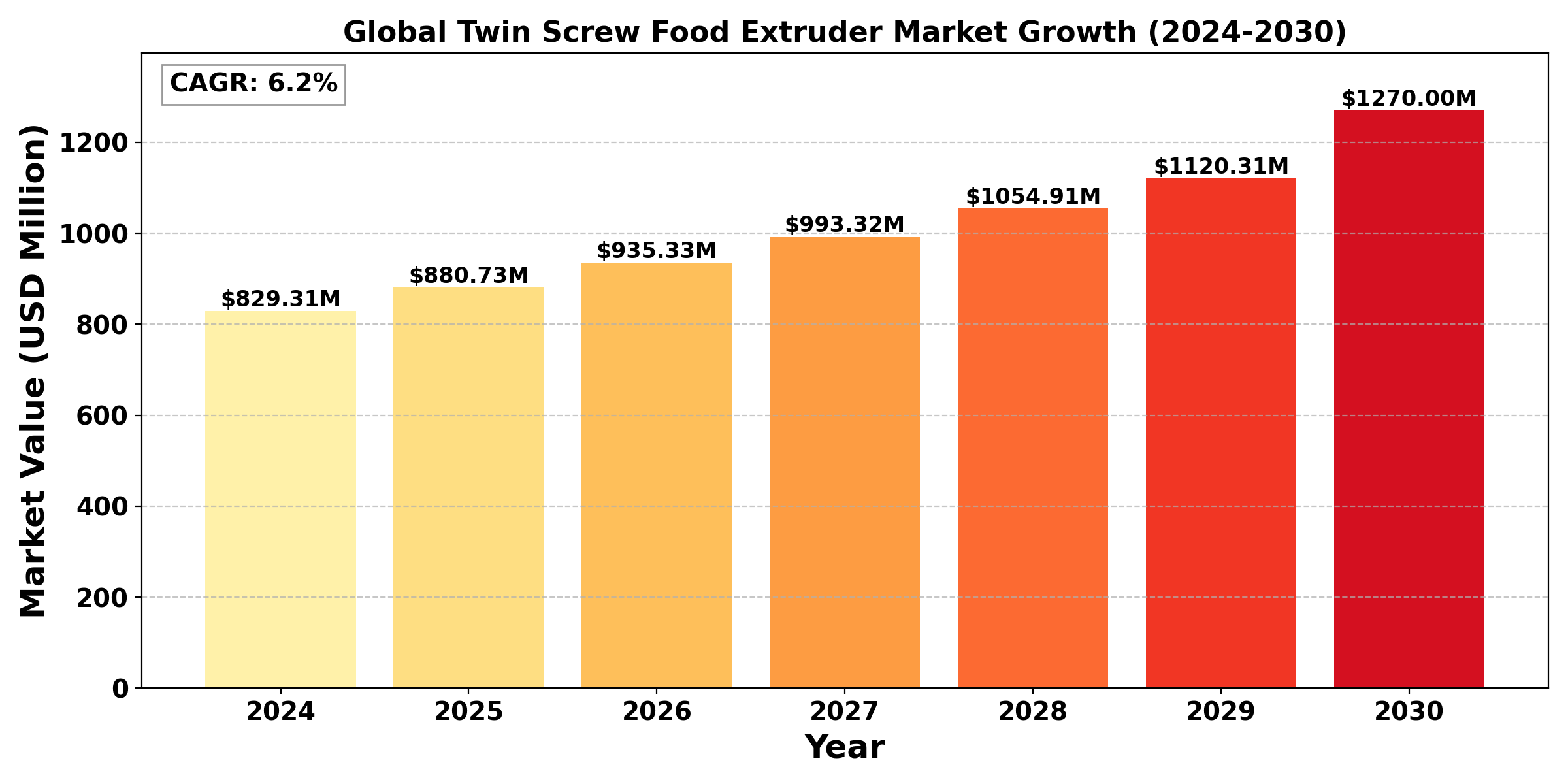

The "Global Twin Screw Food Extruder Market" was valued at USD 829.31 Million in 2024 and is projected to reach USD 1.27 Billion by 2030, growing at a Compound Annual Growth Rate (CAGR) of 6.2% during the forecast period (2024-2030)

The market for twin screw food extruders has been expanding rapidly because of its versatility and effectiveness in processing a variety of food items, including pet foods, textured vegetable proteins, specialty dietary products, and breakfast cereals and snacks. Compared to its single-screw predecessors, twin-screw extruders have several advantages, such as improved mixing, greater versatility when working with components of different viscosities, and the capacity to create intricate shapes and distinctive textures. Because of this adaptability, producers can create novel recipes and formulations to meet shifting consumer demands, such as the need for plant-based proteins, gluten-free goods, and snacks with added nutrients.

The global trend toward convenience meals, which is fueled by busy schedules and the growing urban population, is one of the main factors propelling the market. The pet food market is growing concurrently, and twin-screw extruders are ideally adapted to meet consumer demands for premium, nutritionally balanced pet diets. Additionally, new technology is increasing the efficiency of twin-screw extruders by improving their energy-saving capabilities, simplifying cleaning and maintenance, and improving automation, all of which saves operating costs and downtime.

The growth of the food and beverage s industry has also led to the rising demand for twin-screw food extruders. In Q1 2024, the European food and drink industry production increased by 2.4% compared to the previous quarter. Furthermore, the increasing demand for pet food is also leading to increase demand for twin-screw food extruders. In Europe 29.2 billion euros of pet food are sold annually

➣ Segmental Overview

Fully Automatic twin screw extruders to hold the highest market share: By Type

In the global twin screw food extruder market, fully automatic twin screw extruders hold the most market share. This desire stems from the significant advantages that automation offers the food manufacturing industry, such as improved resource use, consistent product quality, and streamlined processes. To produce food items that satisfy strict quality standards and satisfy a wide range of consumer tastes, fully automatic extruders provide exact control over crucial processing factors including temperature, pressure, and ingredient mixing.

Fully automatic extruders' efficiency also lessens the need for human labor, which is crucial in food processing due to growing labor costs and a lack of qualified operators. The simplicity with which automated extruders may be integrated with contemporary production lines—which frequently have facilities for data collecting, real-time monitoring, and remote troubleshooting—makes them very valuable. Manufacturers can increase overall output and accelerate return on investment by maximizing uptime and minimizing production disruptions because to these capabilities. The manufacturers of twin screw food extruders has also been working towards automation and reduce energy consumption while maintaining high output levels,

For instance: Andritz has introduced a line of fully automated twin screw extruders designed for the pet food and aquatic feed industries, where exact control over product properties is essential. Their most recent innovations, which increase product uniformity and cut down on material waste, include automated ingredient dosing systems and integrated heat management systems.

Co-rotating Twin Screw Extruder to hold the highest market share: By Product Type

The market for twin screw food extruders is dominated by co-rotating twin screw extruders because of their distinctive design and practical benefits, which make them particularly popular in a variety of food manufacturing applications. Both screws in co-rotating twin screw extruders rotate in the same direction, enabling a self-wiping operation that enhances heat transfer, minimizes material accumulation, and guarantees reliable, superior mixing. Because of their design, they are perfect for uses requiring uniform cooking, exact control over texture, and homogeneous ingredient combining. They are therefore frequently employed in the production of snacks, cereals, candies, pet food, and alternative protein products—all of which require a constant level of quality and texture.

Another factor contributing to co-rotating twin screw extruders' prominence in the market is their adaptability. They are versatile to various recipes and formulas since they can work with a broad range of constituents, including liquids, powders, and high-viscosity substances. This flexibility is essential as customer tastes move toward specialist foods that call for sophisticated processing techniques, like plant-based, high-protein, and gluten-free options. Co-rotating extruders are also effective at managing complicated mixtures with several components, allowing producers to create novel goods that satisfy certain dietary preferences and nutritional requirements.

➣ Regional Overview

Despite distinct obstacles and drivers, the global twin screw food extruder market is expanding in every area. Because of its sophisticated food processing industries, high demand for convenience meals, and expanding line of health-conscious products, North America accounts for a sizeable portion of the market. To satisfy strict regulatory requirements and increase production efficiency, the region's well-established companies are concentrating on automation and energy-efficient extruders.

With growing demand for plant-based diets, specialized goods, and eco-friendly packaging options, Europe is another important market. Twin screw extruders are being used more and more by European producers to satisfy strict environmental standards and satisfy the region's strong demand for high-protein, gluten-free, and organic goods. The main drivers of market expansion in this area are environmental initiatives and technological breakthroughs.

Because of increased disposable incomes, urbanization, and a preference for processed and convenience meals, Asia-Pacific is the region with the highest rate of growth. The production of pet food and packaged foods is expanding quickly in nations like China, India, and Japan, which is fueling the need for high-output, adaptable extruders. Asia-Pacific market expansion is also being fueled by the growing number of food processing facilities and government assistance for regional manufacturers.

Africa, the Middle East, and Latin America are developing markets with tremendous potential for expansion. In these areas, the need for effective food processing equipment is growing as a result of population growth, economic development, and shifting consumer preferences for processed foods. Even though these areas already hold a lower portion of the market, growth is anticipated to be supported by international investments and local industries, especially as local food production capacities increase. Growing consumer interest in pet food, snack foods, and processed meals benefits each of these areas, indicating consistent demand growth for twin screw extruders over the next several years.

➣ Competitive Analysis

➣ Recent Development:

GEA launches its new xTru Twin 140 extruder completing its range of high-capacity output equipment. The new top-of-the-range machine is equipped with an advanced profile; powered screws provide users up to 40 percent increased capacity with the same efficiency, quality and footprint as previous models.

➣ End-Use Industry Analysis:

A number of important end-use industries are served by the twin screw food extruder market, and demand is driven by these industries' unique processing requirements as well as consumer trends. Convenience foods and snacks make up a significant share of the market since twin screw extruders are perfect for creating a variety of textures and shapes, which are crucial for the innovation-driven expansion of the snack sector. Manufacturers can now efficiently produce high-quality, consistent snack products thanks to extruders, as consumers want quick, on-the-go solutions.

Another end-use market that is expanding quickly is the pet food sector. Demand for extruders that can create specialty pet foods with consistent texture, form, and nutritional profiles has increased as pet ownership has increased and pet owners place a higher priority on high-quality nutrition. Twin screw extruders are preferred because of their accuracy and capacity to manage the precise ingredient mixtures needed for high-end pet treats, particularly fully automated ones. An estimated sixty-six percent of U.S. households, or about 86.9 million families, own a pet, according to the 2023-2024 National Pet Owners Survey conducted by the American Pet Products Association (APPA). Furthermore, Total pet industry expenditures in the U.S. totaled $147 billion in 2023, up 7.5 percent from $136.8 billion in 2022.

➣ Industry Dynamics

➣ Industry Driver

Growing Demand for Convenience Foods

Convenience food consumption is on the rise due to urbanization, changing nutritional tastes, and increasingly hectic lifestyles. Customers look for quick, easily available, and minimally prepared food options as they balance work, social obligations, and family life. Among younger customers and working professionals, who frequently value expediency above traditional meal preparation, this tendency is especially evident.

Twin screw extruders play a key role in satisfying this demand since they allow producers to create a variety of processed foods, cereals, and ready-to-eat snacks. These extruders' technology guarantees excellent efficiency, adaptability, and accuracy, enabling the consistent quality and texture that today's discriminating consumers demand. In keeping with the health-conscious trends that are increasingly affecting the convenience food industry, twin screw extruders also provide the flexibility to incorporate a variety of components, including whole grains, proteins, and other nutrients. The global frozen food market size was estimated at $280 billion USD in 2018, and is projected to expand at a CAGR of 4.3% from 2019 to 2025.

Additionally, manufacturers can experiment with new flavors, textures, and shapes via twin screw extruders, satisfying a market that appreciates diversity and cutting-edge culinary experiences. Manufacturers can use twin screw extrusion technology to create trendy items that appeal to changing customer tastes and remain competitive, such as plant-based, low-calorie, and protein-rich snacks.

Additionally, manufacturers can experiment with new flavors, textures, and shapes via twin screw extruders, satisfying a market that appreciates diversity and cutting-edge culinary experiences. Manufacturers can use twin screw extrusion technology to create trendy items that appeal to changing customer tastes and remain competitive, such as plant-based, low-calorie, and protein-rich snacks.

➣ Industry Trend

Focus of Sustainability

Manufacturers in all industries, including the food industry, are now primarily focused on sustainability. The food industry are under growing pressure to implement more sustainable methods, cut waste, and lessen their carbon footprint as environmental concerns grow. Stricter sustainability rules and rising customer demand for eco-friendly items are the main drivers of this change. As a result, producers are searching for processing technologies that adhere to environmentally friendly standards while simultaneously producing high-quality goods.

The increasing focus on sustainability in the food business is a perfect fit for twin screw extruders. These devices have a number of significant benefits in this regard, beginning with their resource and energy efficiency. When compared to more conventional cooking techniques like steam cooking or batch procedures, twin screw extruders can save energy usage by streamlining the cooking process. This helps manufacturers lessen their carbon footprint by lowering operating expenses and having a smaller environmental impact.

Industry Restraint

A major factor for many food manufacturers, especially small and medium-sized businesses (SMEs), is the substantial capital expenditure needed to purchase fully automatic twin screw extruders. Even though twin screw extruders have several advantages in terms of productivity, product quality, and adaptability, their high initial cost might be a major deterrent, particularly in developing nations where finance options may be scarcer.

Fully automatic twin screw extruders are extremely sophisticated devices that incorporate intricate features like high throughput, precision processing, and automated control systems. These characteristics help explain why they cost more than more basic, conventional processing equipment. The initial cost may still be too high for companies that are not yet able to make such a significant investment, even though it can result in long-term benefits through decreased energy usage, decreased waste, and quicker production cycles.

➣ Report Scope

The report includes Global & Regional market status and outlook for 2017-2028. Further, the report provides breakdown details about each region & countries covered in the report. Identifying its sales, sales volume & revenue forecast. With detailed analysis by Type, Product type, Process, Application, . The report also covers the key players of the industry including Company Profile, Product Specifications, Production Capacity/Sales, Revenue, Price, and Gross Margin 2017-2028 & Sales with a thorough analysis of the market’s competitive landscape and detailed information on vendors and comprehensive details of factors that will challenge the growth of major market vendors.

|

Attributes |

Details |

|

Segments |

By Type

By Application

By Application

By Process

|

|

Region Covered |

|

|

Key Market Players |

|

|

Report Coverage |

|