TOP CATEGORY: Chemicals & Materials | Life Sciences | Banking & Finance | ICT Media

Industry Overview

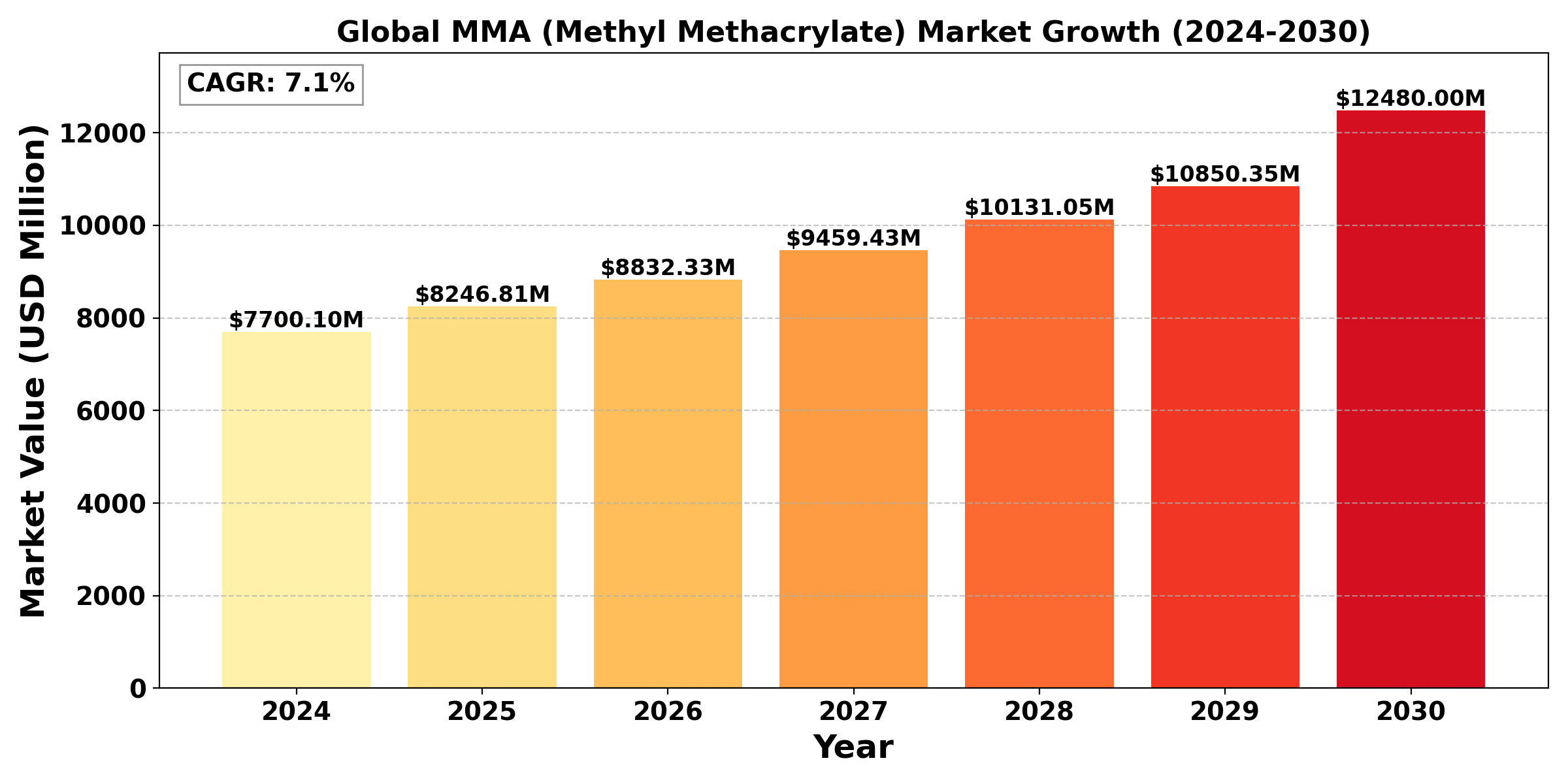

The "Global MMA (Methyl Methacrylate) Market" was valued at US$ 7700.1 Million in 2024 and is projected to reach US$ 12480 Million by 2030, at a CAGR of 7.1% during the forecast period.

The global Methyl Methacrylate (MMA) market is driven by its versatile applications across diverse industries, including automotive, construction, electronics, and healthcare. As a key raw material in producing polymethyl methacrylate (PMMA) and other copolymers, MMA is crucial for manufacturing transparent and lightweight materials, particularly in automotive and electronics applications where durability and aesthetics are essential. Increasing demand for lightweight and fuel-efficient vehicles has propelled MMA's usage in automotive manufacturing, where it contributes to weight reduction and improved design flexibility. Additionally, MMA is widely utilized in paints, coatings, and adhesives, essential for high-performance finishes in construction and electronics.

Since MMA is mostly obtained from petrochemical sources, it is vulnerable to changes in the price of oil, which presents issues for the market. Environmental rules pertaining to emissions and waste management also put additional strain on manufacturers, increasing the demand for MMA substitutes made of biomaterials. However, growing building activity in emerging nations and technological developments in MMA production processes that improve sustainability and efficiency have kept the market upbeat. With manufacturers concentrating on sustainability and cutting-edge applications to satisfy changing consumer preferences, the MMA market is anticipated to rise steadily as a result of these trends.

Segmental Analysis

Industrial Grade holds the highest market share: By Type

When compared to experimental grade, industrial grade caustic soda has the largest market share. The production of pulp and paper, chemical processing, textiles, water treatment, aluminum, soap, and detergent are just a few of the large-scale industries that use industrial-grade caustic soda extensively. It is appropriate for these difficult operations, which call for bulk quantities and dependable performance, due to its high purity and constant concentration levels.

Due to its affordability and suitability for large-scale industrial operations, where it is necessary for processes including neutralization, pH correction, and material breakdown, industrial-grade caustic soda is widely used. Experimental-grade caustic soda, on the other hand, is mostly utilized in specialist applications, research, and laboratories where lesser amounts are required but great purity and accuracy are required. Because of this, experimental-grade caustic soda is a specialized market with a small market share. Because it is still necessary for many different industries, industrial-grade caustic soda is in high demand, maintaining its market leadership.

Plastic to hold the highest market share: By Application

In the caustic soda market, plastic production holds the highest market share among the listed applications. The manufacture of PVC (polyvinyl chloride), a plastic that is extensively used in the consumer goods, automotive, and construction industries, depends heavily on caustic soda. Because PVC is so durable and adaptable, it is used for everything from flooring and window frames to pipes and fittings, which creates a significant need for caustic soda in the plastics industry. Urbanization, infrastructural development, and the expanding need for building materials worldwide—especially in emerging markets—all contribute to the demand for PVC and, by extension, caustic soda. Caustic soda's use in this sector is sustained by the fact that plastics continue to be a crucial component as industries target lightweight, long-lasting, and reasonably priced materials. Other applications, such as coatings, adhesives, and organic glass, also contribute to the caustic soda market but on a smaller scale. Compared to the production of plastic, these applications typically call for caustic soda in more specialized or specific functions, resulting in lower volumes. As a result, the plastics sector consumes the most caustic soda, highlighting its important contribution to the expansion of manufacturing and industry worldwide.

Regional Analysis

The market for methyl methacrylate (MMA) is a significant sector of the global chemicals industry, driven by robust demand from a variety of applications, including electronics, medical devices, construction, and trucks. Because of its exceptional durability, clarity, and resistance to weather, MMA is mostly employed in the production of polymethyl methacrylate (PMMA) resins, coatings, and adhesives. In line with the industry's transition to electric and fuel-efficient vehicles, the automotive sector uses MMA to create lightweight, highly-strengthened components. Growth is also being fueled by the building industry's need for acrylic-based goods in windows, signage, and coatings. To increase sustainability, the market must contend with issues including raw material instability and environmental laws, which has led to investments in the manufacturing of MMA derived from biomaterials

Regions like Asia-Pacific, particularly China and India, are experiencing robust growth due to increasing industrialization and urbanization, positioning these markets as pivotal players in global MMA consumption.

Competitive Landscape

The competitive landscape of the methyl methacrylate (MMA) market is characterized by a large number of regional manufacturers in addition to well-known international firms like Mitsubishi Chemical, Dow, LG Chem, and Arkema. In this fast-paced industry, major competitors are vying for market share through a combination of product innovation, strategic alliances, and expansions. Leading businesses are investing in sustainable technology, such as bio-based MMA and recycled PMMA, with a focus on cost-effective production, in order to meet the growing demand from customers for environmentally friendly solutions and to handle mounting regulatory challenges. Price competition is still fierce because of changes in the price of raw materials and the entry of new competitors from developing nations.Additionally, geographic expansion in high-growth regions like Asia-Pacific, with its robust manufacturing and construction sectors, has become a strategic focus. Innovation in production methods, such as lower-emission and energy-efficient processes, is also providing competitive advantages, helping companies cater to end-users' needs while navigating environmental regulations. The competitive intensity in this market is further amplified by the need for scale economies and supply chain resilience, especially in regions prone to disruptions.

Recent Development

May 2022, Evonik and Vimal Intertrade and Nordmann expand their strategic distribution cooperation for Evonik's VISIOMER® Specialty Methacrylates in India. Evonik has selected a new distribution arrangement for its VISIOMER® Specialty Methacrylates in order to effectively meet the various market demands and better serve the developing Indian and neighboring markets. This information was obtained from

February 2022, Sumitomo Chemical to Create New MMA Division In order to bolster its MMA business, which includes acrylic resin (PMMA, polymethyl methacrylate) and MMA (methyl methacrylate) monomer, Sumitomo Chemical has chosen to create a new MMA Division effective April 1, 2022. The new section will be in charge of the company's overall strategy development, worldwide marketing, and sales.

End Use Industry Analysis

The end-use market for methyl methacrylate (MMA) includes a number of rapidly expanding industries, including electronics, medical devices, signage, automotive, and construction. MMA is mostly utilized in the automotive sector to create strong, lightweight parts like external panels and glass, which complements the drive for fuel economy and advancements in electric vehicles. Because of its clarity and durability, which meet both functional and aesthetic objectives, MMA is in high demand in the construction industry for architectural materials, windows, coatings, and weather-resistant acrylic sheets. Key applications for MMA-derived polymers, such as polymethyl methacrylate (PMMA), include electronics and consumer products. PMMA offers great optical clarity, impact resistance, and insulation for screens, lenses, and protective covers.

Furthermore, in the medical area, where performance and safety are critical, MMA's sterilizing resistance and biocompatibility make it perfect for applications like dental and bone cement. MMA's contribution to recyclable and bio-based materials is becoming more significant across industries as sustainability concerns increase. Rapid urbanization, economic expansion, and industrialization are reflected in the rising demand from emerging markets, especially in Asia-Pacific, which makes MMA crucial to meeting the changing demands of these industries.

Industry Dynamics

Industry Drivers

Rising demand from the Automotive Sector

The growing demand from the automotive industry, which places a greater importance on MMA's lightweight, robust, and adaptable qualities, is one of the main factors propelling the methyl methacrylate (MMA) market. Because of its high strength-to-weight ratio, impact resistance, and optical clarity, MMA is becoming more and more popular as automakers work to reduce vehicle weight in order to increase fuel efficiency and adhere to strict pollution standards. Because of these qualities, MMA is a perfect material for making vehicle parts like windows, light covers, displays, and external panels. Additionally, the demand for MMA has increased due to the trend towards electric vehicles (EVs), as EV design necessitates lightweight materials to enhance battery efficiency and range. Because of MMA's resilience to weather and UV rays, car exteriors last longer, require less care, and increase in value over time.

Furthermore, as businesses seek to reduce waste and increase environmental responsibility, MMA's recyclability fits perfectly with the sustainability objectives of the automotive sector. The need for MMA is expected to increase steadily as vehicle ownership rises globally, particularly in emerging nations where urbanization and rising incomes fuel automotive sales. This will further cement MMA's position as a crucial component in assisting the automotive industry's changing demands and sustainability initiatives.

Industry Trend

Growing Shift towards sustainable and bio-based MMA production

Growing environmental restrictions and customer demand for eco-friendly materials are driving a significant development in the methyl methacrylate (MMA) industry: the move towards sustainable and bio-based MMA manufacturing. Conventional MMA manufacturing mostly uses petrochemical feedstocks, which have a large carbon footprint and are prone to price volatility. In response, businesses are spending money on R&D to create MMA using sustainable resources, like bio-based methanol, which can lessen environmental effect without sacrificing material performance. Additionally, the industry is adopting recycling techniques like depolymerization, which enable the breakdown and repurposing of goods created from MMA, establishing a closed-loop system consistent with the tenets of the circular economy.As end-use industries like electronics, construction, and automotive prioritize sustainability in their materials to meet regulatory criteria and enhance brand impression, this trend is especially pertinent. Further lowering the environmental impact of MMA manufacture is the availability of more energy-efficient production techniques made possible by technical advancements. As global awareness and demand for green materials continue to grow, nations such as North America and Europe, which have strict sustainability rules, are setting the bar for other regions to follow in adopting these sustainable MMA practices.

Industry Restraint

The price volatility of raw materials, especially for petrochemical-based feedstocks like acetone, methanol, and hydrogen cyanide, is one of the major barriers to the methyl methacrylate (MMA) business. Due to variables including shifting crude oil prices, supply chain interruptions, and geopolitical conflicts, these materials—which are essential for the manufacturing of traditional MMA—are susceptible to price swings. This kind of uncertainty can drive up manufacturing costs and reduce profit margins, particularly for smaller businesses who lack vertical integration or substantial purchasing power. Furthermore, because MMA production requires a lot of energy, growing energy prices drive up manufacturing costs even more, which affects pricing flexibility and competitiveness. Increasing regulatory demands, particularly in North America and Europe, where strict environmental regulations necessitate expensive compliance procedures like waste management and emissions reductions, exacerbate these raw material difficulties. Businesses who can't afford these extra expenditures run the danger of losing market share to less expensive alternatives like polycarbonate and polyethylene, which are occasionally chosen for their affordability. The demand for bio-based MMA is being driven by sustainability concerns, but the change is being hampered by high production costs that restrict the affordability and scalability of green alternatives. All of these elements work together to limit market expansion, particularly in areas with strict regulations and price sensitivity.

Report Scope

The report includes Global & Regional market status and outlook for 2017-2028. Further, the report provides breakdown details about each region & countries covered in the report. Identifying its sales, sales volume & revenue forecast. With detailed analysis by Type, Application. The report also covers the key players of the industry including Company Profile, Product Specifications, Production Capacity/Sales, Revenue, Price, and Gross Margin 2017-2028 & Sales with a thorough analysis of the market’s competitive landscape and detailed information on vendors and comprehensive details of factors that will challenge the growth of major market vendors.

|

Attributes |

Details |

|

Segments |

By Type

By Application

|

|

Region Covered |

|

|

Key Market Players |

|

|

Report Coverage |

|